|

| August 17, 2021 | Volume 17 Issue 31 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

NASA's Quiet SuperSonic test plane takes shape at Skunk Works

The team at Lockheed Martin Skunk Works in Palmdale, CA, has merged the major sections of the X-59 Quiet SuperSonic Technology aircraft, which includes the wing, tail assembly, and fuselage or forward section. This marks the first time the X-59 resembles an actual aircraft. [Credit: Lockheed Martin]

By Sasha Ellis and Evan Flatt, NASA Langley Research Center

A heavy chorus of bolting and machinery filled the X-59 Quiet SuperSonic Technology, or QueSST, assembly building as engineers, system technicians, and aircraft fabricators worked to merge the major aircraft sections together, making it look like an actual aircraft for the first time since the initial cut of metal in 2018.

"We've now transitioned from being a bunch of separate parts sitting around on different parts of the production floor to an airplane," said Jay Brandon, NASA chief engineer for the Low Boom Flight Demonstrator (LBFD) project.

NASA's single-seater X-59 QueSST is under construction at Lockheed Martin Skunk Works in Palmdale, CA, and is designed to fly at supersonic speeds -- approximately 660 mph at sea level -- without producing a startling sonic boom for people on the ground.

The X-59's unique shape controls the way the air moves away from the plane, ultimately preventing a sonic boom from disturbing communities on the ground.

This artist concept of NASA's Quiet SuperSonic Technology jet reflects the airplane's final configuration following years of research and design engineering. The jet is now under construction by Lockheed Martin at the company's Skunk Works facility. [Credits: Lockheed Martin]

NASA will work with U.S. communities to understand their response to the aircraft's sound and provide that data to regulators, which could change the rules that currently ban supersonic flight over land, cutting travel time in half for some air travelers in the near future.

The merger

With great precision and accuracy, the team used features on the structure to precisely self-locate the aircraft's wing, tail assembly, and fuselage or forward section, then employed a series of laser projections to verify the precise fit.

"The extensive use of features and pre-drilled, full-size fastener holes has significantly reduced the time it takes to locate and fit parts, especially mating large assemblies like this," said David Richardson, Lockheed Martin program director. "It is sort of like how Legos go together. We used the laser tracker to make sure it is all aligned per the engineering specs before we permanently bolted it all together."

VIDEO: Time-lapse of X-59 Quiet SuperSonic Technology aircraft assembly (May 2019 - June 2021) [Credit: NASA]

The mating of these major hardware components was a breath of fresh air for the team.

"A milestone like this -- seeing the airplane coming together as a single unit -- really reinvigorates and motivates the team," said Dave Richwine, NASA's LBFD deputy project manager for technology.

Fuselage

The aircraft's fuselage contains the cockpit and helps define the shape of the X-59. Eventually, the 30-ft-long nose of the aircraft will be mounted to the fuselage.

Part of the cockpit is something you might see in an office. The pilot will see the sky ahead through a 4K computer monitor, which will display complex computer-processed imagery from two cameras mounted above and below the X-59's nose. NASA calls this forward-facing "window" the eXternal Vision System or XVS.

Cockpit visualization: The pilot of NASA's X-59 QueSST aircraft will navigate the skies in a cockpit unlike any other. There won't be a forward-facing window -- it's actually a 4K monitor that serves as the central window and allows the pilot to see traffic in his or her flight path and provides additional visual aids for airport approaches, landings, and takeoffs. [Credit: NASA]

The XVS serves as an aid to help the pilot maneuver safely through the skies. This cutting-edge vision system is necessary because the desired shape and long nose of the X-59 won't allow for a protruding cockpit canopy.

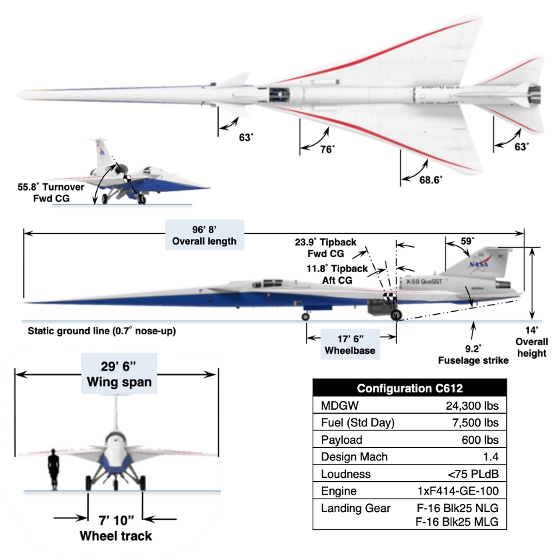

X-59 Quiet SuperSonic Technology Demonstrator specs. [Images courtesy: NASA]

Wing

The most recognizable part of the airplane -- the wing -- was "the most complicated section and first section of the X-59 that was fabricated by Lockheed Martin," explained Richwine. Housed within the 29.6-ft-wide wing are the aircraft's fuel systems and a large portion of its control systems.

The Lockheed Martin team used robotic machines with names that sound like pilot call signs -- Mongoose and COBRA -- to manufacture the wing before its mate to the tail assembly and fuselage.

Mongoose is a tool with the ability to weave together composite wing skins using ultraviolet light to bind the composite material. COBRA (Combined Operation: Bolting and Robotic AutoDrill) efficiently created holes that allowed the team to attach the wing skins to the wing frame.

Tail assembly

The tail assembly contains the engine compartment. This section is built with heat-resistant materials that protect the aircraft from the heat given off by the X-59's GE F414 engine.

GE F414 engine. [Credit: NASA/GE]

The engine is in the upper section of the X-59. Similar to the XVS, it is one of many purposeful design elements that ensure the aircraft is shaped as desired to produce a quieter noise to people below.

What's the point of the X-59 -- apart from it just being 'plane' cool?

The X-59 (the visual centerpiece of the mission) definitely brings in the cool factor, but the data part of NASA's mission (the nerdy part) is what will revolutionize speedy commercial air travel over land.

NASA's quiet supersonic mission involves building the X-59 (happening now) and conducting initial flight tests starting in 2022.

In 2023, NASA will fly the X-59 over the test range at the agency's Armstrong Flight Research Center in California to prove it can produce a quieter sonic thump and is safe to operate in the National Airspace System. More than 175 ground recording systems will measure the sound coming from the X-59.

In 2024, NASA will fly the X-59 over several communities around the nation to gauge people's response to the sonic thump sound produced by the aircraft -- if they hear anything at all. The data collected will be given to the Federal Aviation Administration and the International Civil Aviation Organization for their consideration in changing the existing bans on supersonic flight over land.

That ban went into effect in 1973 and has plagued commercial supersonic ventures ever since, restricting faster-than-sound travel only to flights over the ocean. British Airways and Air France flying the Concorde were two airlines that offered such service between 1976 and 2003.

If rules change because of NASA's data, a new fleet of commercial supersonic aircraft become viable, allowing passengers to hop on a plane and arrive from distant destinations in half the time. Though the single-piloted X-59 will never carry passengers, aircraft manufacturers may choose to incorporate its technology into their own designs.

The future awaits

With an eye to the future, the team is rigorously working on final assembly of the X-59, which will mark the end of manufacturing.

In late 2021, Lockheed Martin will ship the X-59 to a sister facility in Ft. Worth, TX, where ground testing will be done to ensure the aircraft can withstand the loads and stresses that typically occur during flight. There, the team also will calibrate and test the fuel systems before the X-59 makes the journey back to California for more tests.

Though seemingly a long way away, community overflights, data collection, and a possible new commercial market for supersonic flight over land is just around the corner.

SIDEBAR: Skunk Works' rules

By Jim Banke, Aeronautics Research Mission Directorate, NASA

Perhaps it's only fitting the future of commercial supersonic aviation in the form of the X-59 is being built by the company responsible for the fastest airplane in history -- the SR-71 Blackbird -- using innovative production processes that go back 76 years.

"The purpose of us building the X-59 at the Skunk Works isn't really for us to pioneer new manufacturing technologies. It's to use what we know works well to get the airplane built and flying for our customer," said Mike Buonanno, a Lockheed Martin aerospace engineer who is the company's vehicle lead for the X-59.

That's not to say the company isn't using the most modern technology available in delivering their aircraft. It is.

But what makes the Skunk Works unique in its approach to manufacturing is embodied in 14 rules originated by aviation legend Kelly Johnson, who led the Lockheed team in World War II that designed and built the nation's first jet fighter -- the XP-80 -- in only 143 days.

Those rules call for small teams, simple approaches, close communication, streamlined paths of authority, and a healthy dose of common sense all summarized by the words quick, quiet, and quality.

Today, that manufacturing heritage is guiding Lockheed Martin as it builds the one-of-a-kind X-59.

"We still hold true to those rules that Kelly Johnson came up with 76 years ago, especially of having engineers on the floor ready to respond to issues, with the key goals of keeping drills drilling and wrenches turning on a regular basis," said Tom Alexander, Lockheed Martin's special projects operations manager.

Part of a wing spar for NASA's X-59 Quiet SuperSonic Technology airplane is prepared for installation by a pair of Lockheed Martin technicians working at the company's Skunk Works factory. [Credits: Lockheed Martin]

The X-59 assembly work taking place on the Lockheed Martin production floor is concentrated within three major sections of tooling.

The forward jig is home to the X-59's fuselage (the center section to the airplane's single-piece wing), and the rear jig is set up for the fabrication of the airplane's tail holding the vertical fin and the horizontal stabilizer (a section also known as the empennage).

Most of the activity right in the beginning was focused on the fuselage and wing jigs, but the empennage section is busy too now.

Initial flight tests to ensure the vehicle is operating in 2022 will be followed by a series of supersonic flights to validate if it is producing quieter sonic booms as expected. After that, the X-59 will begin its community overflights to gather public response data, with the plan to present that information to the FAA and others.

"Sometimes building an airplane is a little tough, but having that exciting end goal really helps keep the team energized," Buonanno said.

Published August 2021

Rate this article

View our terms of use and privacy policy